What makes a VSI Valve

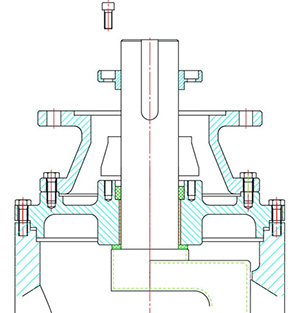

Standard Bonnet

Standard VSI Waterworks valves include a removable bolted bonnet. This allows direct operator mounting and includes flanges to either ISO 5211 or MSS SP101 depending on the project requirements.

By eliminating additional brackets and couplers, VSI Waterworks is able to reduce cost and even allow untrained personnel to mount these operators.

Whether the desired operator is a manual gear, electric actuator, pneumatic actuator, or any number of other operators, all operators on the market come with these standard mounts.

Buying from a company that does not comply with these widely accepted standards is buying outdated equipment.

Adjustable Packing

Unlike the majority of our competitors who use o-rings as shaft seals, VSI Waterworks is committed to using only the leading v-packing ring designs.

While this adds slight complexity to the assembly of the valve, it assures that the valve will not leak through the stem under any condition.

The packing is fully adjustable and in some instances replaceable while the line is under full pressure.

The packing is not reliant on the operator to maintain a seal on the shaft as some of our competitors.

Standard Premium Materials

All VSI Waterworks valves use ductile iron as a standard for bodies and discs/gates.

With a tensile strength over double that of the cast iron our competitors use, ductile iron is the ideal valve material.

In addition, all shafts are stainless steel 304 as standard. The EPDM for our seats and seals is peroxide cured or sulfur cured.

Call 770-740-0800

To Speak With Our Engineering Team